Technical Blog

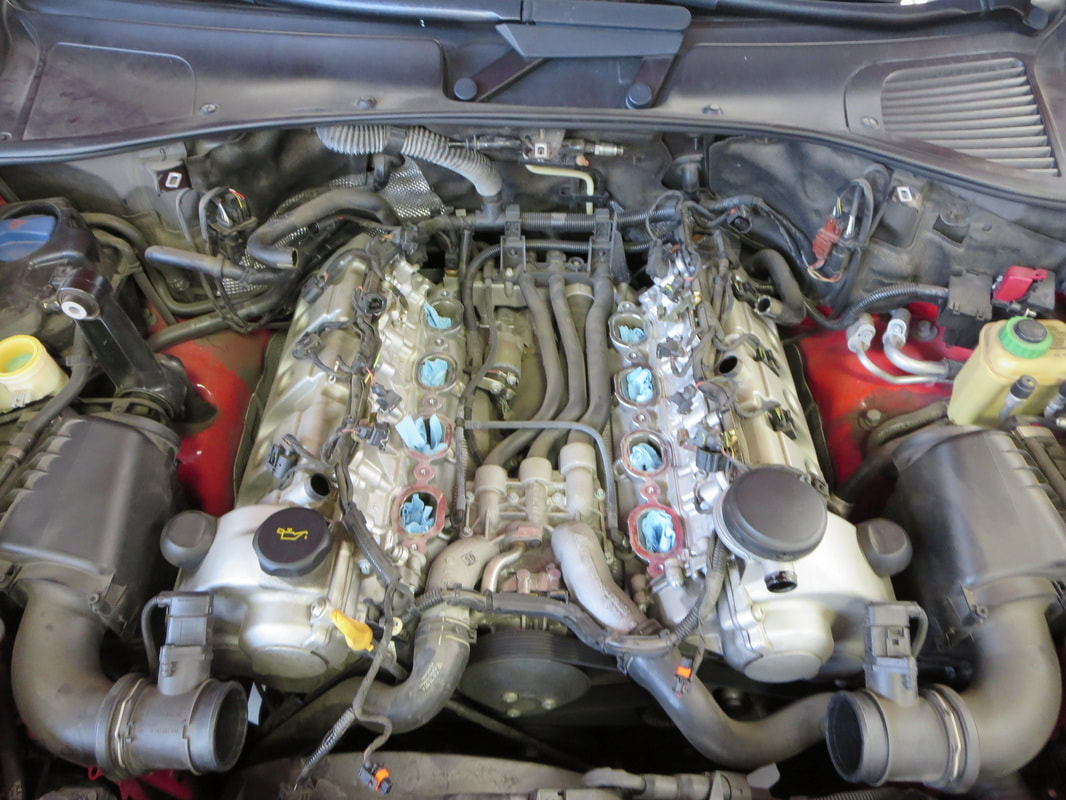

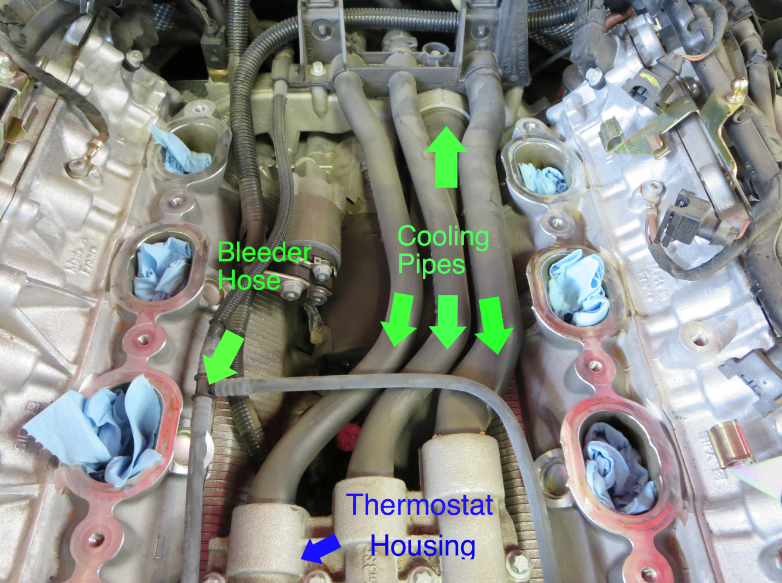

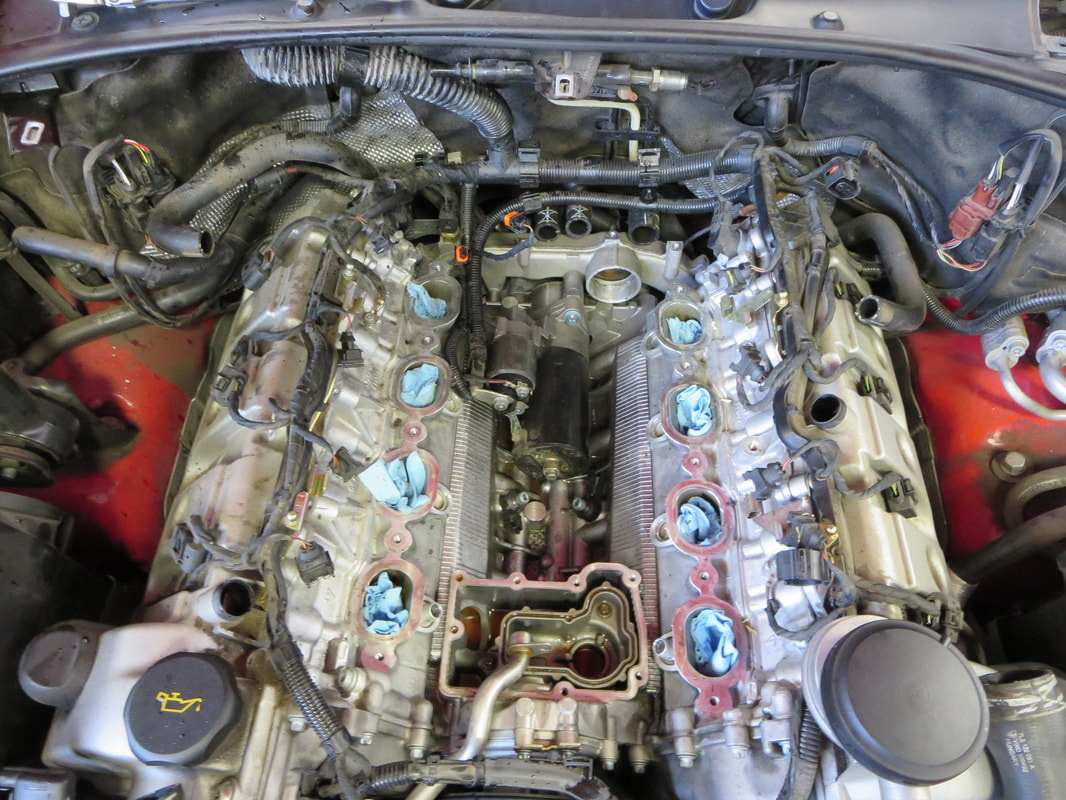

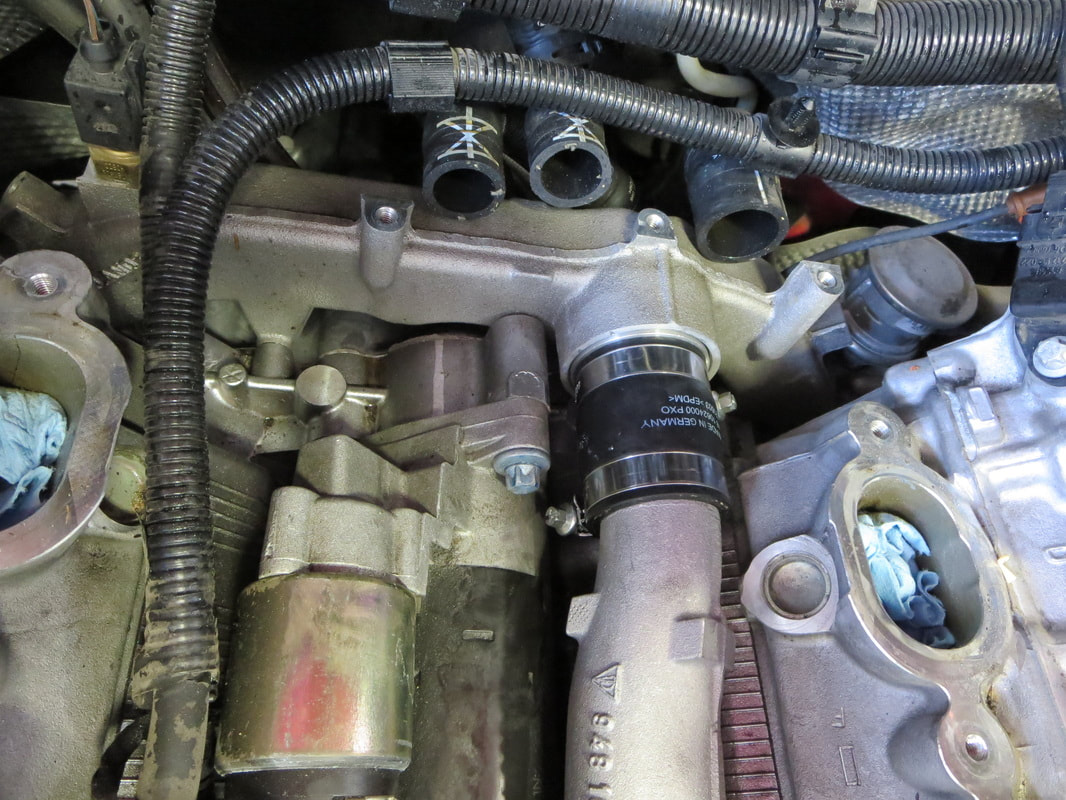

Cayenne Cooling Pipe Failure10/2/2013 I doubt the engineers at VAG expected this to happen. And that's okay, right? We're human and this is no Radio Flyer wagon. The early Cayenne models that are equipped with V8 engines have an achilles heel: The plastic pipes that carry coolant located underneath the intake manifold are cracking, effectively spilling coolant to the external surfaces of the engine: right where you don't want it to be. This causes inconvenience, unforseen expense and grave disappointment because it's a Porsche Sports SUV and this kind of thing just shouldn't be happening! Here is a glimpse of this unfortunately common problem and what we do to solve it. Click on the photos to enlarge and read on......

0 Comments

Your comment will be posted after it is approved.

Leave a Reply.Joe LeggsHusband, Father, Technician Archives

October 2016

Categories |

RSS Feed

RSS Feed