Technical Blog

Routine maintenance, regular inspections and keen eyes and ears can help prevent costly damage. If you are tracking your car or running high horsepower applications it is important to have your equipment checked more frequently. Wear and tear can never be eliminated in these situations but costly repairs can be avoided if an issue is rectified before it becomes severe.

0 Comments

Oil Hose Repair and Rebuilding9/14/2016 In the day to day grind of a repair or restoration shop, parts are replaced and discarded without a second thought. If parts are available, which in most cases they are, replacement makes sense- the costs of restoring or rebuilding a component generally outweighs the cost of a new one. Inconvenience to all is lessened. It makes sense, right? I tend to be nerdy about this stuff and I tend to be green, too. If I can rebuild it or repair it, I want to almost every time. I hate waste. Why waste a new part when the old one can be like new with a little work? In the early days of my journey into this field of work, the transition between rebuild and replace was beginning. Technicians were craftsman...they were rebuilding and repairing parts daily. Not so much to save their client's money but because it was the normal way of doing things. I learned that way. I accepted that way of thinking and still practice it in my daily work. Oil Line Repair While performing some restorative work to a 1977 911 Turbo, I was shocked to find that the oil pressure hoses connecting both to and from the scavenge pump were not available. My natural approach was to rebuild them. No problem- solution found. I rebuilt the cam feed lines, too. Here are some pictures of my repair. This situation called for line rebuilding for a few reasons: 1. The vehicle's owner didn't want to upgrade to hydraulic chain tensioners. 2. he didn't want to replace the lines with 'new' looking lines that were zinc coated. He wanted to retain an original appearance.

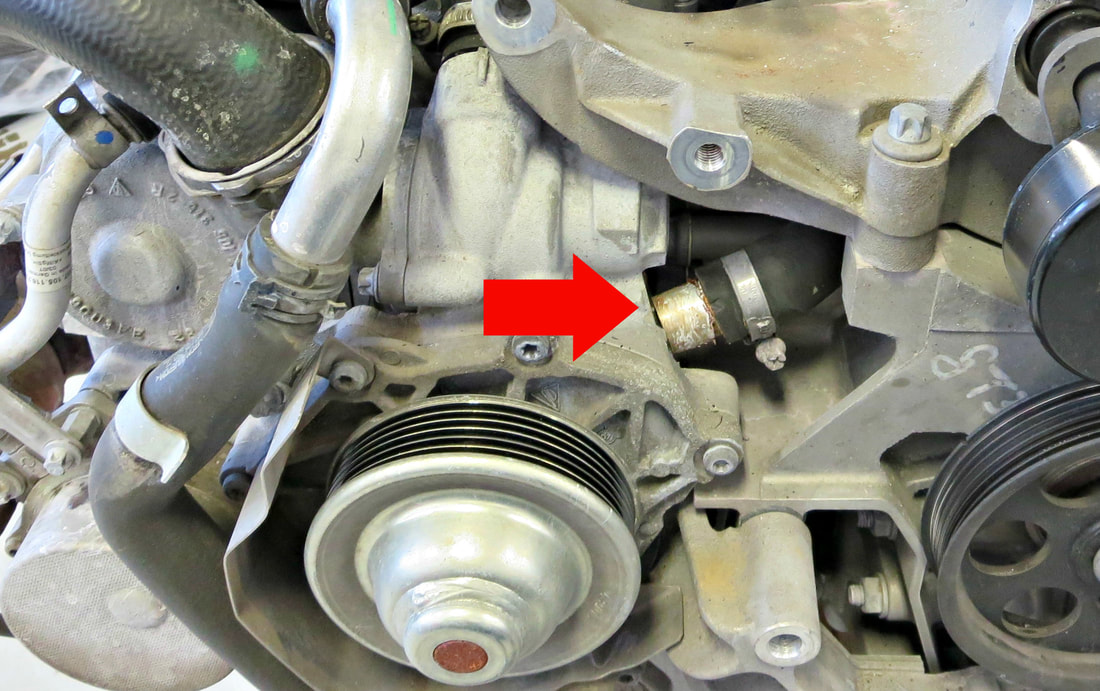

This worked out nicely for the turbo feed and scavenge pump lines, too! Thanks for reading! Your worst nightmare: popping a cooling pipe on the back straight of your local track at 6,500 RPM effectively emptying your cooling system and overheating your engine in seconds. Luckily, the Mezger-based 996 and 997 engines are extremely resilient. This doesn't mean that you shouldn't prevent this failure from occuring. Successful ownership experience with a Porsche Turbo, GT2 and GT3 begins with preparation. 'When' Not 'If' Start preparing- there's no better time than now to take action. While you're beginning to budget and plan your repair, here are some factors to consider: PathologyThe coolant block housings are made from cast aluminum while the pipe that the hoses clamp-to are made from extruded aluminum. Porsche engineers know that cast and extrusions expand and contract differently so they secured the pipes into the cast with an epoxy designed to expand and contract as well. Due to the rapid temperature changes in the engine compartment(my theory) and other factors, the epoxy can work loose and leave you roadside(or trackside) with potential engine damage not to mention inconvenience and expense. What They Look Like Below is an image of a cooling pipe that has come loose. The epoxy(brown substance) is in some cases not strong enough to retain the pipe. Note the pink residue beneath: this is evidence of coolant leakage before the pipe actually popped out. In most cases, popping pipes can be prevented. Periodic inspection can catch this failure before it happens! Repair Options Welding: At first glance, replacing the pipes and welding them into the cast housings looks and sounds great. Who can argue with how good this looks? Unfortunately, cast aluminum components are porous and don't react well to welding. The heat inflicted pores will increase in size and generally cause future leaks. We've seen some circumstances where welding the pipes works and doesn't leak. A good quality casting and a gifted welder can produce good results with the right amount of luck. After some time, however, they will most likely look like this: Again- more pink residue is a sure sign of a leaking coolant. Even after a bulletproof weld, this cooling pipe can't stop seeping. Pinning: Another solution is to 'pin' the pipes to prevent their loosening. Simply put, anchoring the pipes into their cast housings with a high grade epoxy that can expand and contract with the metal coupled with a bolt that secures the pipe is a viable, cost effective solution that wont' disrupt the metal and guarantee it's integrity. We prefer this method. Here's how it will look: The following method will produce a long lasting solution:

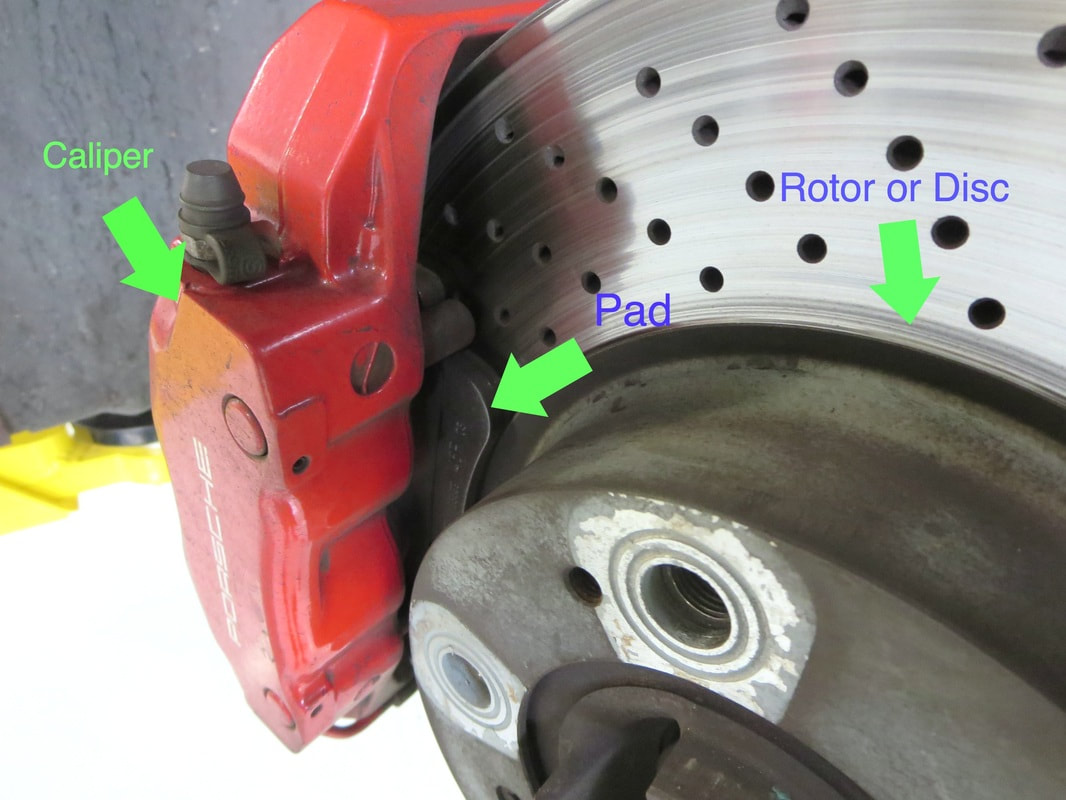

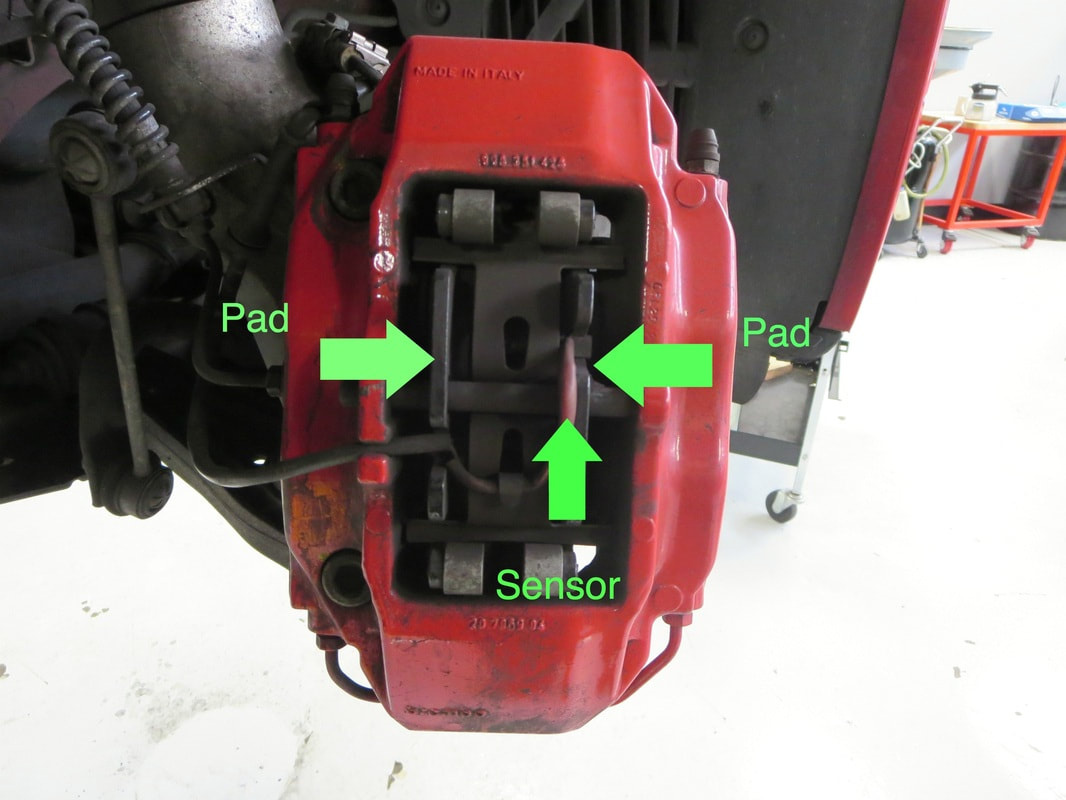

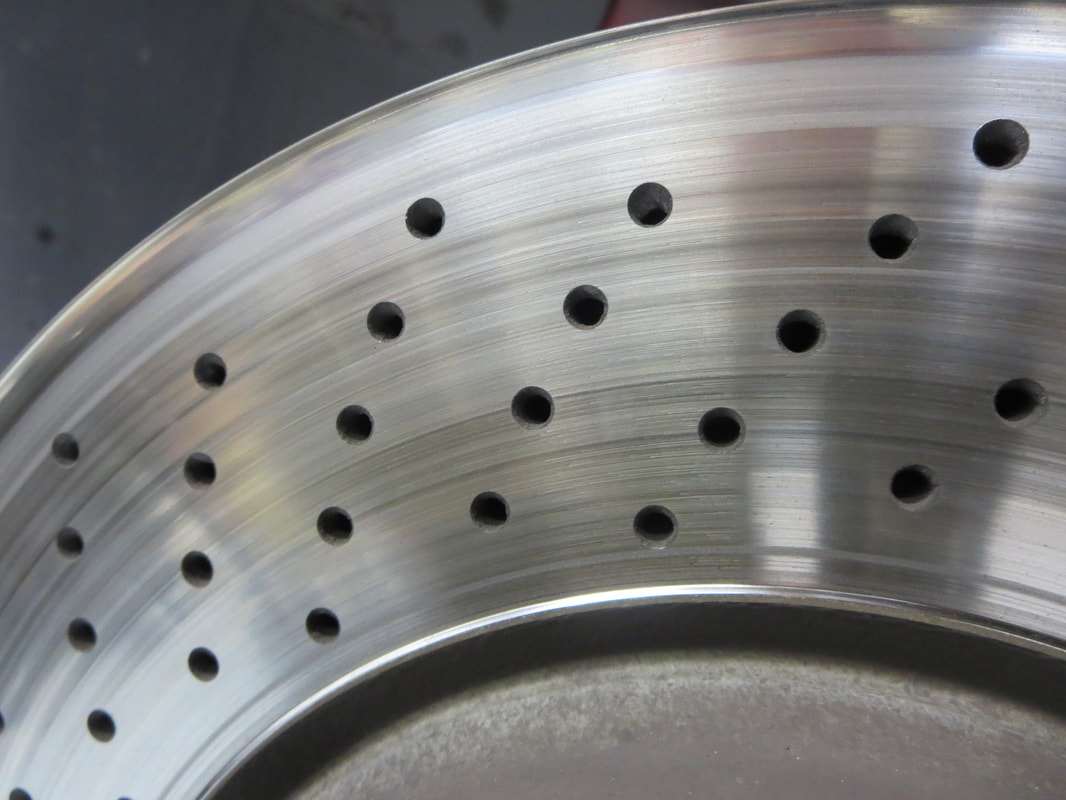

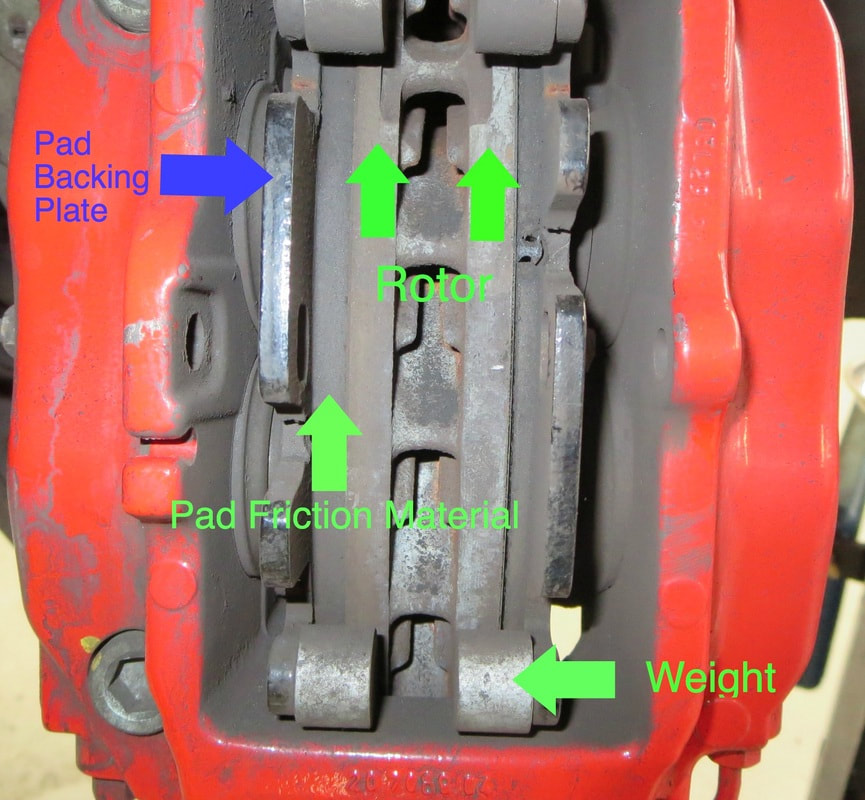

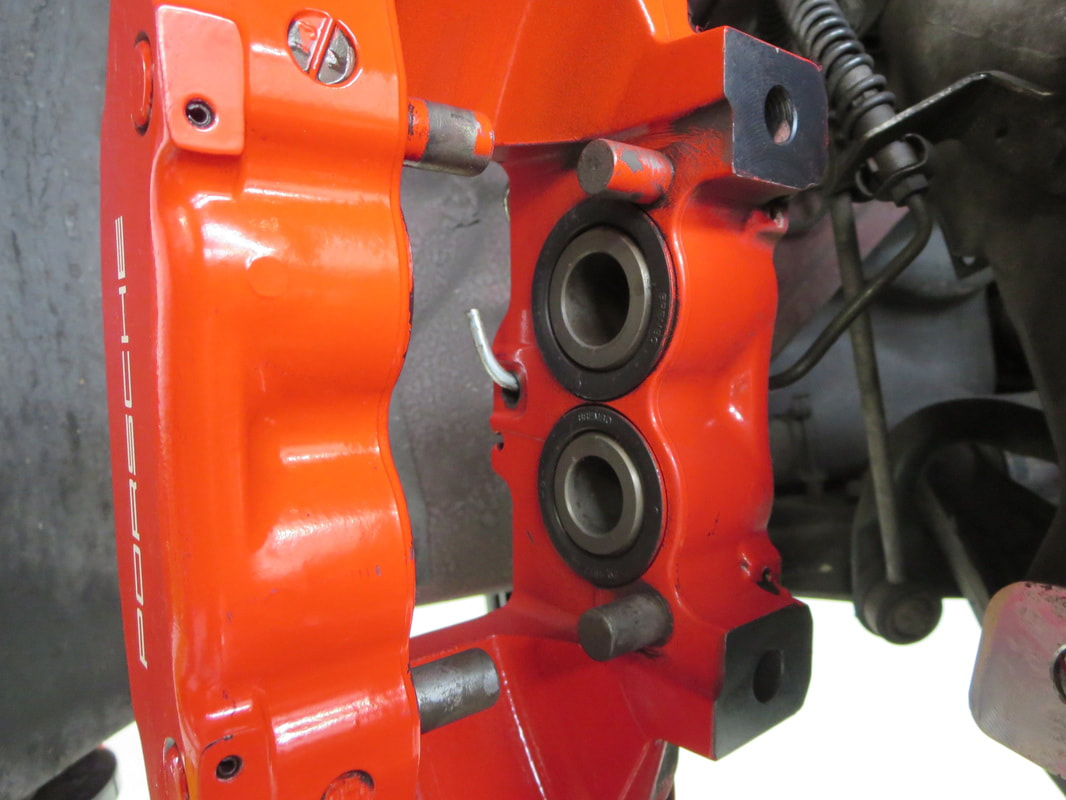

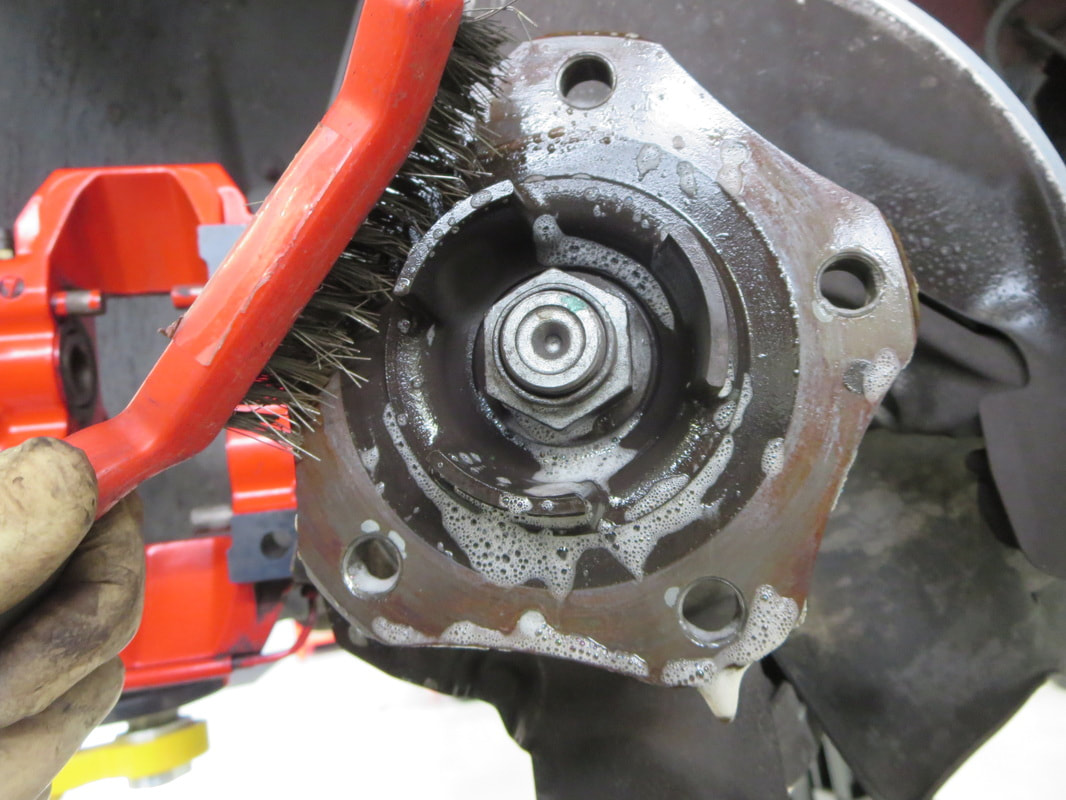

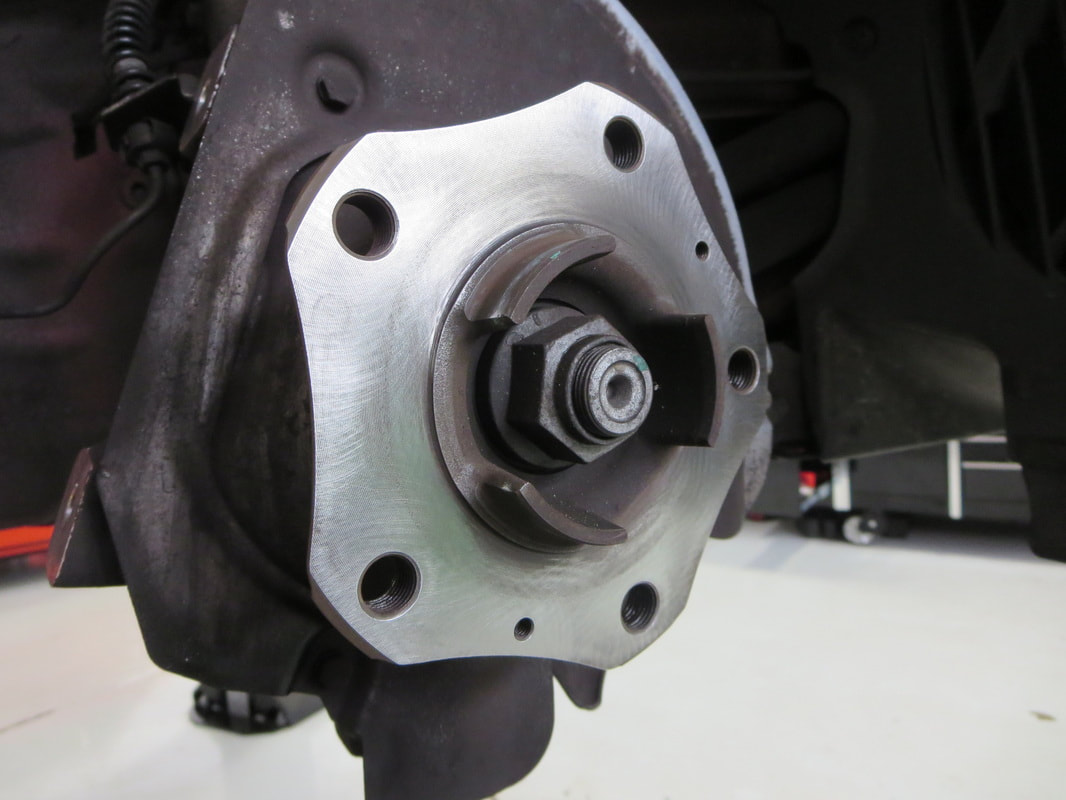

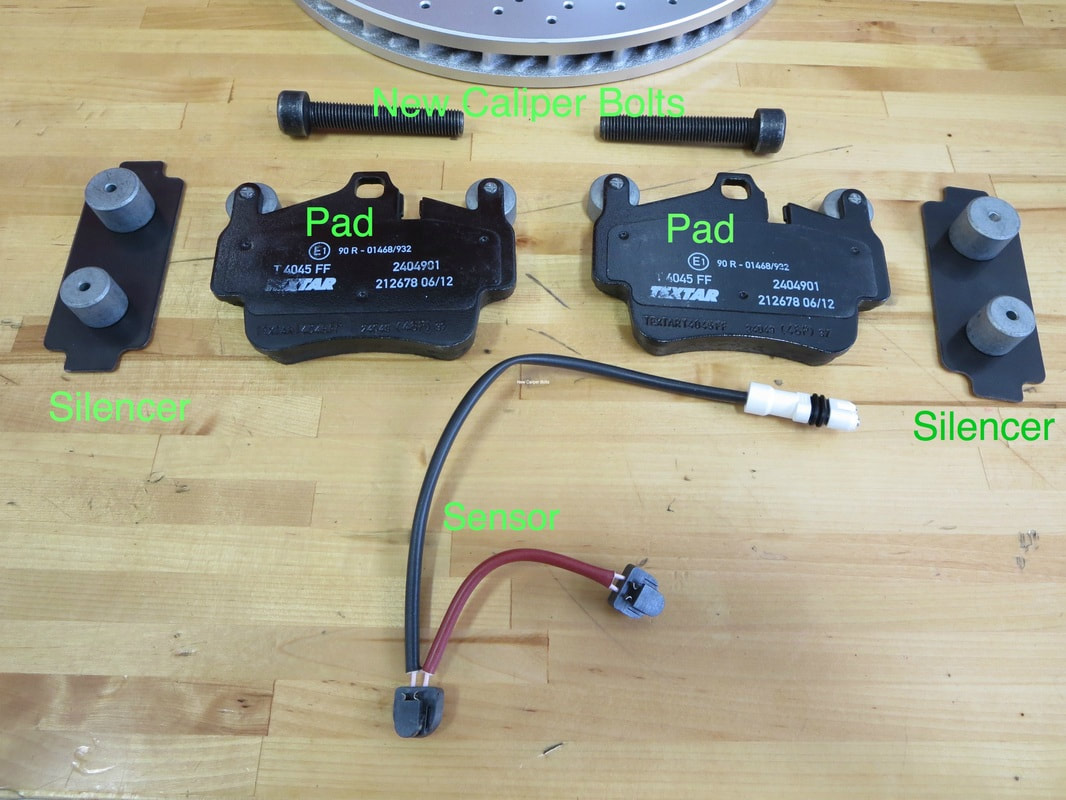

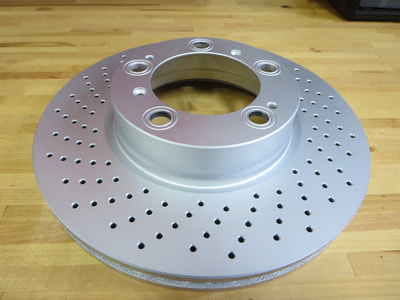

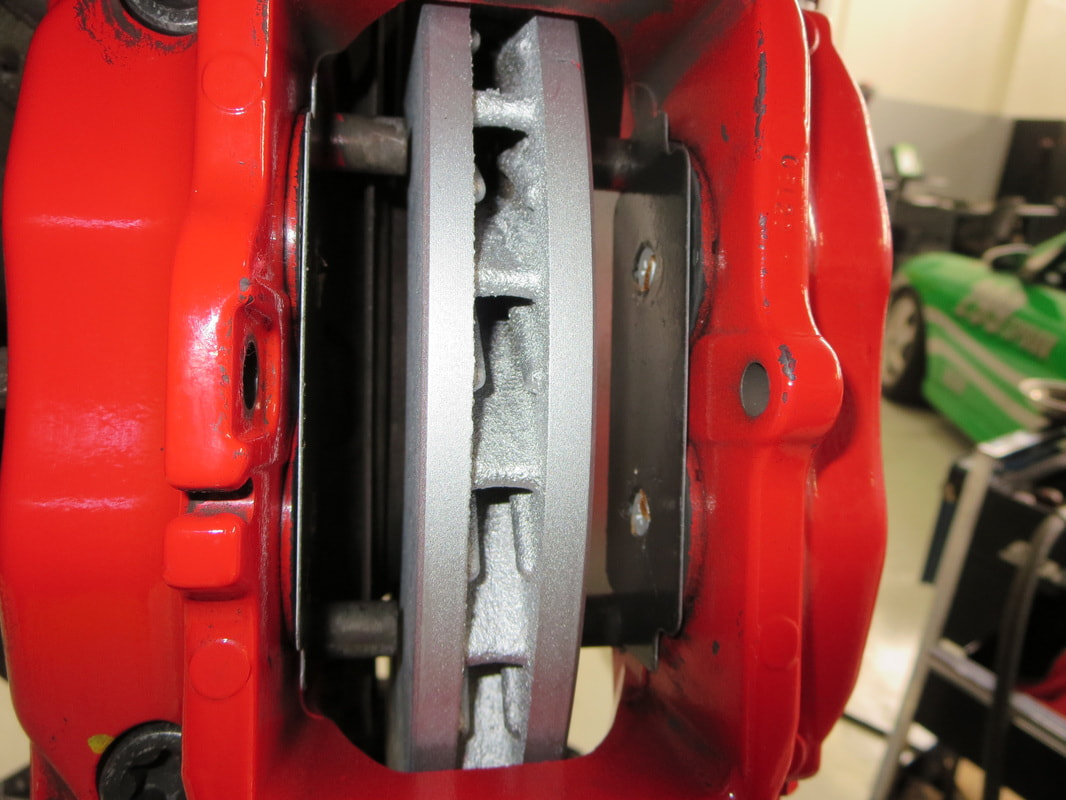

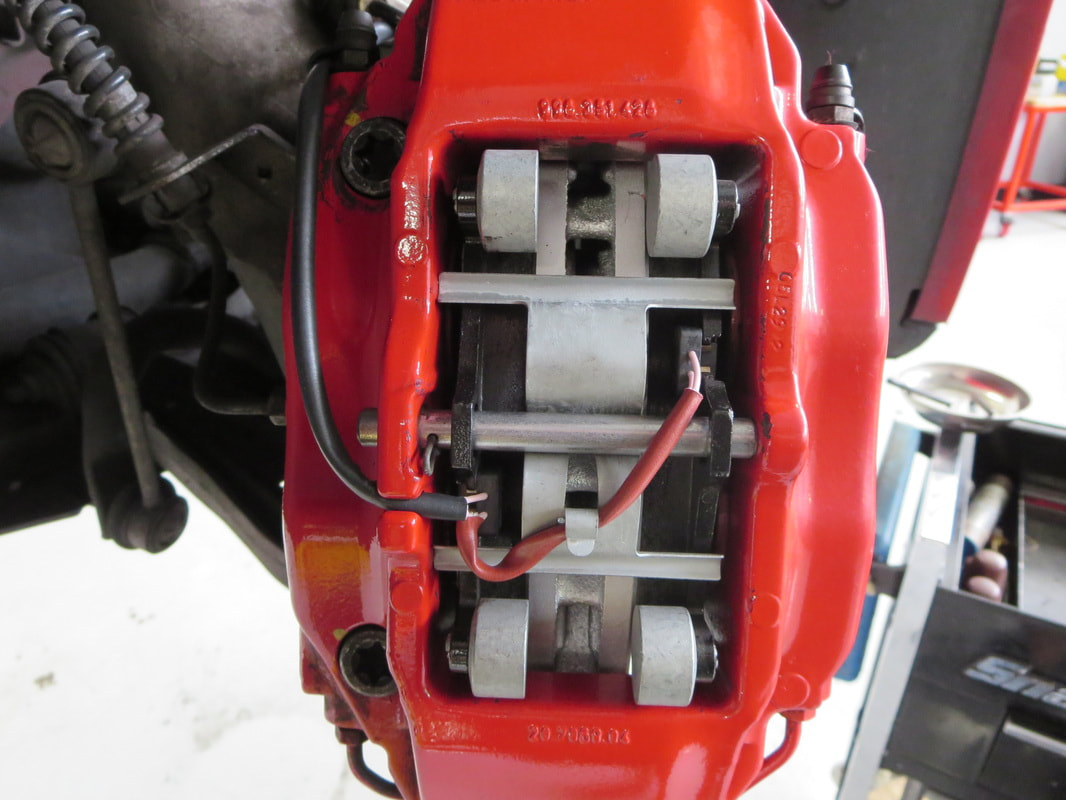

A hole is drilled and tapped to fit a stainless button-head allen screw. The screw's length is equal to the thickness of the material so that it does not impede flow. We use thread sealant on the screw during installation to prevent leakage. The inside of the pipe is cleaned and wire brushed to ensure no debris remains after modification. Brake Service Our Way3/18/2016

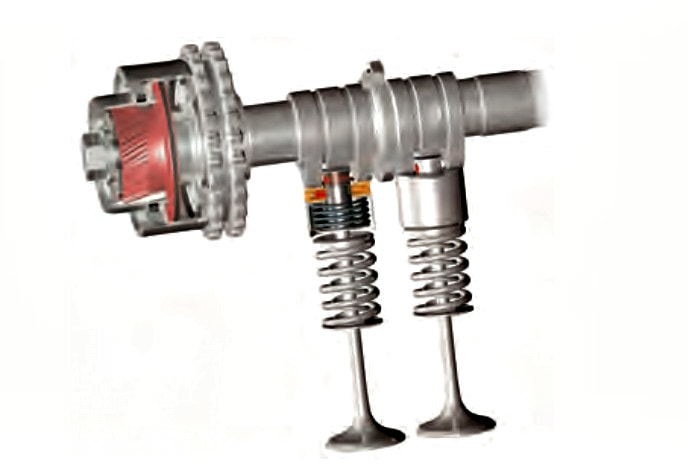

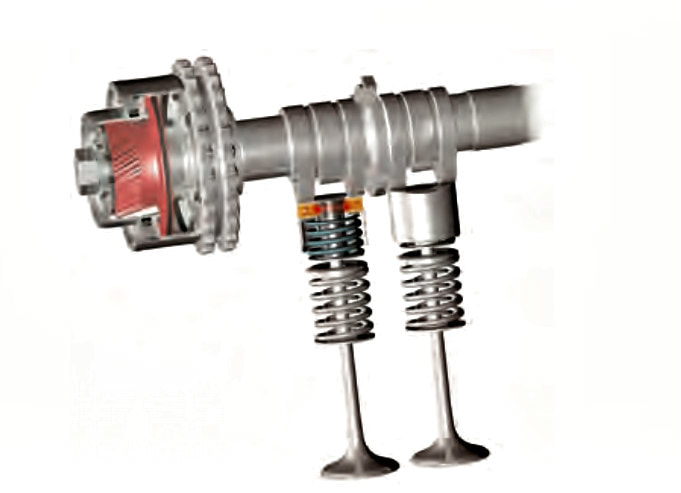

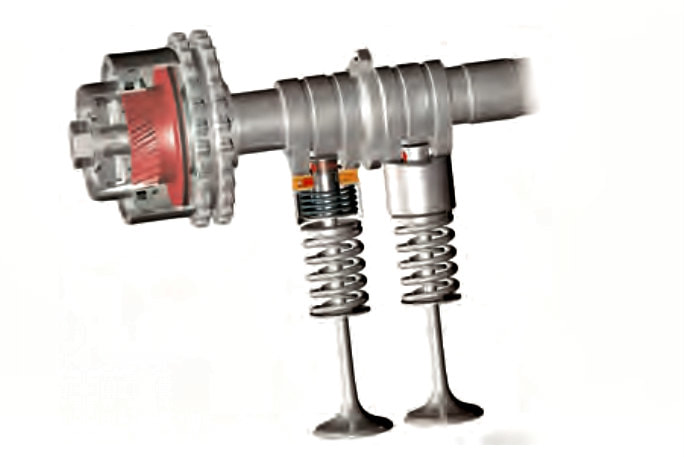

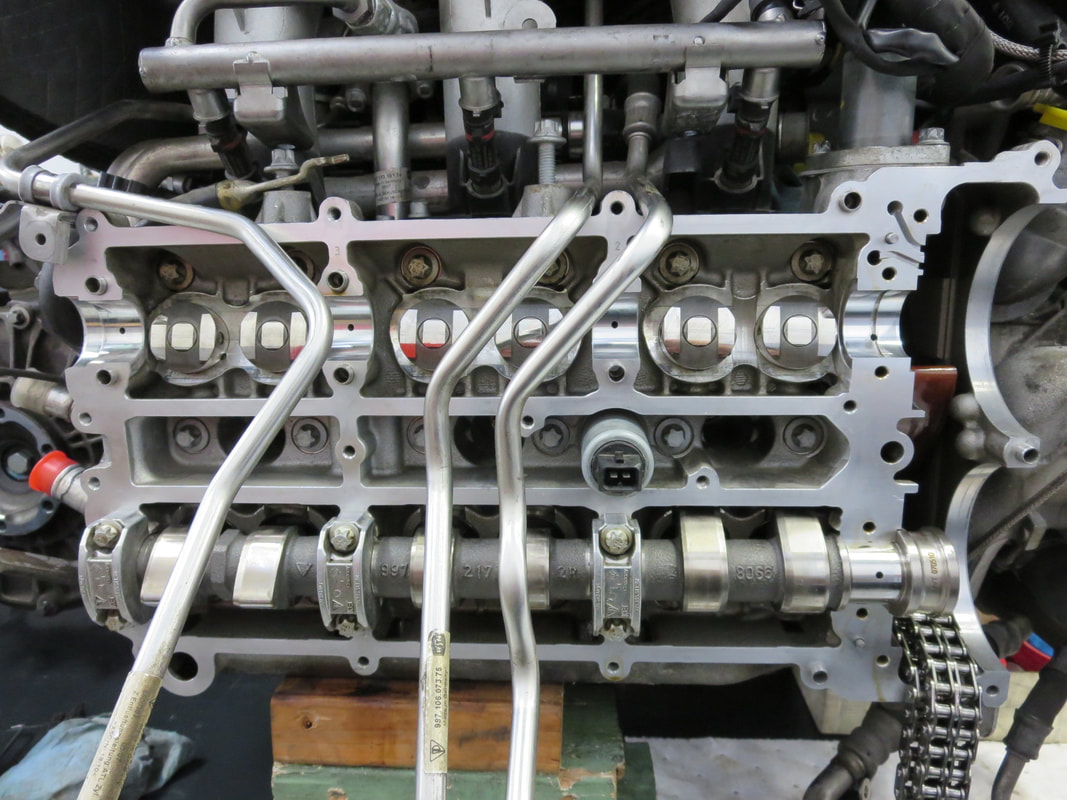

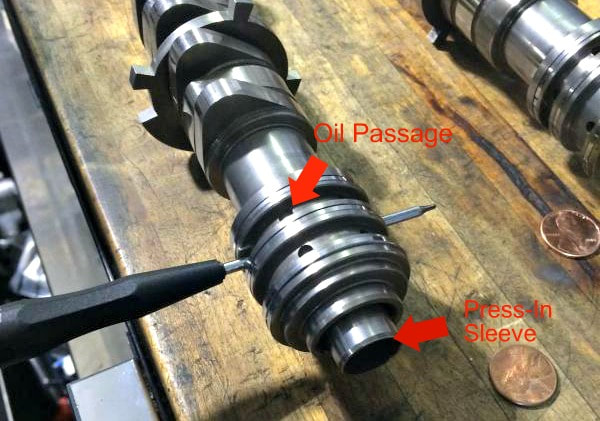

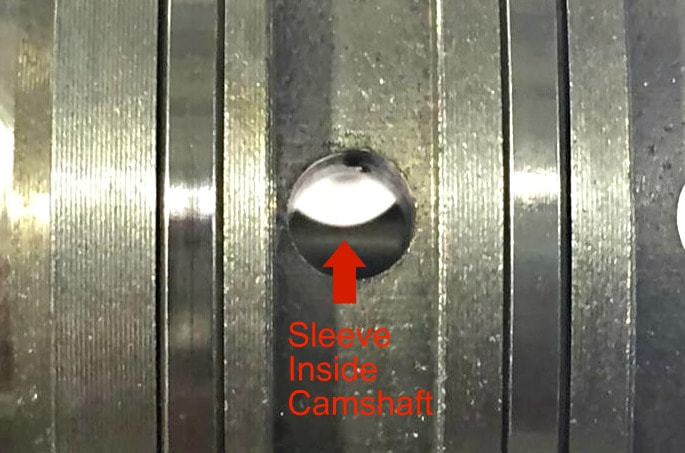

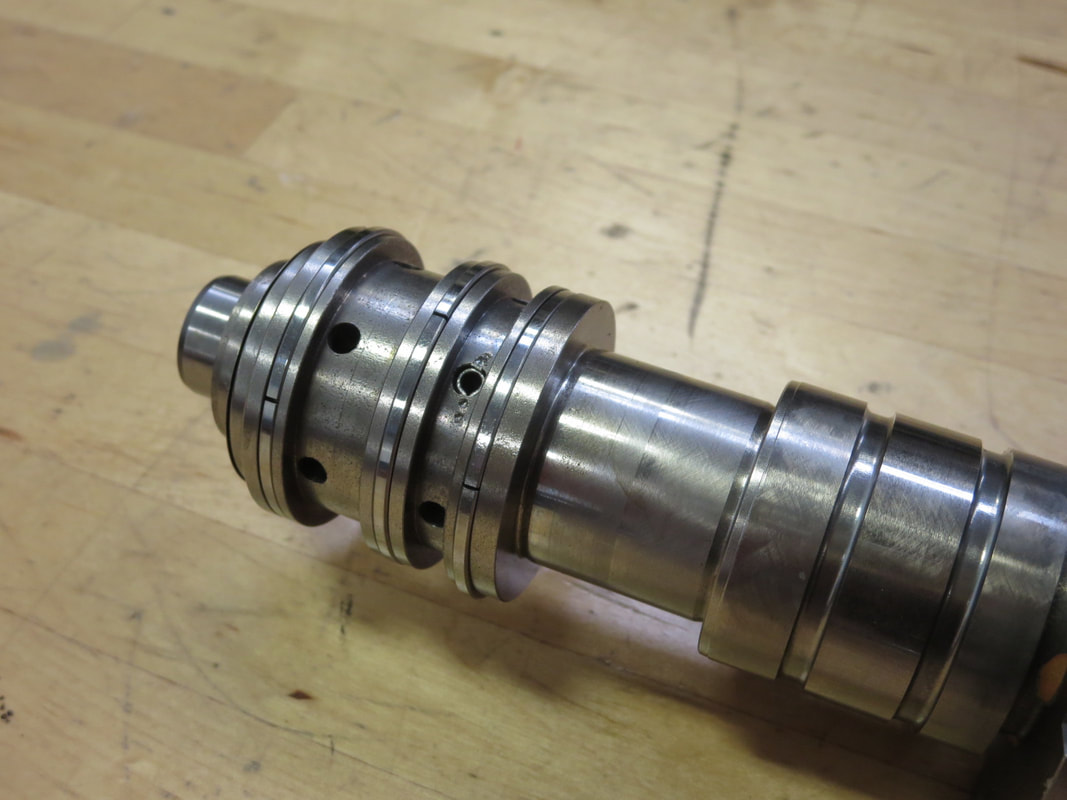

Fuel Injection Pressure Hose Repair12/15/2015 Nearly all of the Porsche and Ferrari production cars assembled between the late 70's and the late 80's were equipped with Bosch CIS mechanical fuel injection system. The Bosch CIS(Continuous Injection System) is a durable, fairly efficient and maintenance-free injection system designed to compensate for altitude, cold and warm starts as well as real time mixture by way of the Lambda(Oxygen) Sensor. The two enemies of this system are storage and age. Each of these cause a CIS Injection system to develop leaks and corrosive buildup. These issues can be prevented by periodic inspection and strategic repairs. Don't be scared off by a CIS injected vehicle. These systems have proven their reliability time and time again, as many cars on the road today still run the original injection components. Maintained properly, these systems will provide years of solid, dependable service. Here's a glimpse of a repair we performed recently on a mid-eighties powerhouse! One of the reasons that we love the Porsche 997 Turbo/GT2 so much is their Variable Turbine Geometry's reduced lag. This, coupled with Variable Valve Lift and Timing(on the intake cam, at least) help this engine deliver smooth and powerful performance throughout it's range of RPM. Let's take a closer look at why this is so badass. Porsche's VarioCam Plus VarioCam Plus is Porsche's unique way of utilizing your engine's oil pressure to activate an adjustment inside an variable camshaft sprocket to actively(while the engine is running) adjust camshaft timing(see the change in red below). Changes in valve lift occur when oil pressure is directed to affect the two-stage lifters. These lifters will lock and open the valves further with the help of special camshafts thus increasing output.

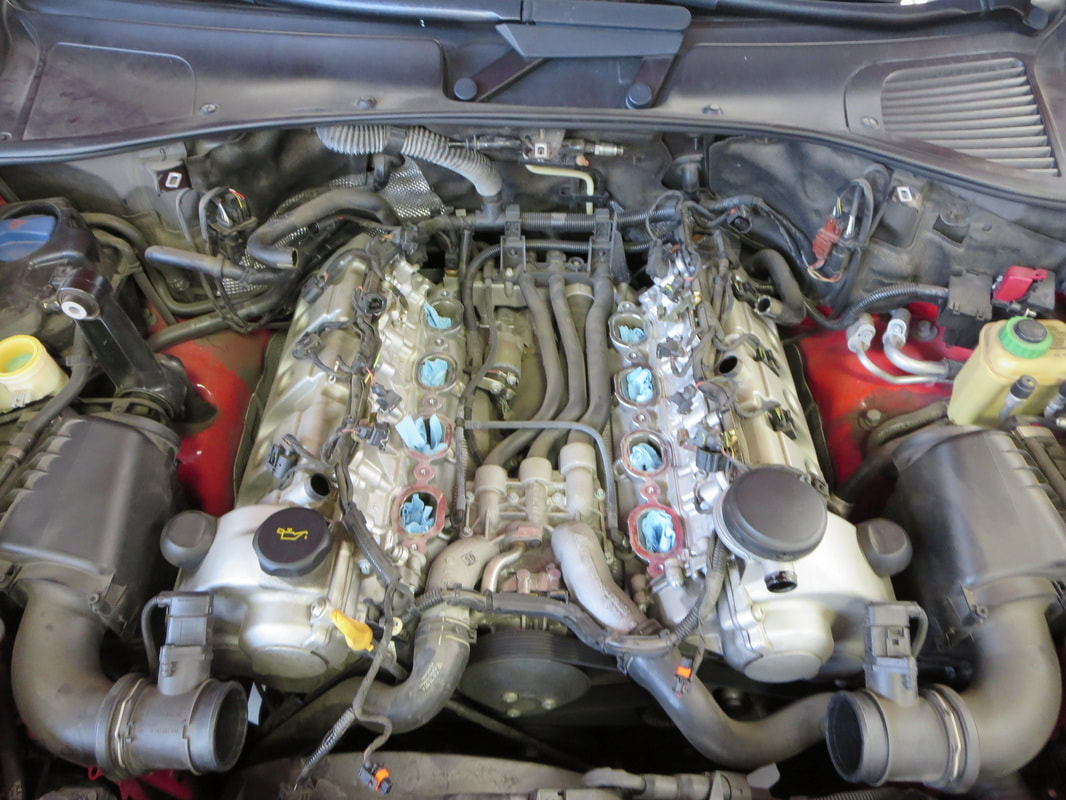

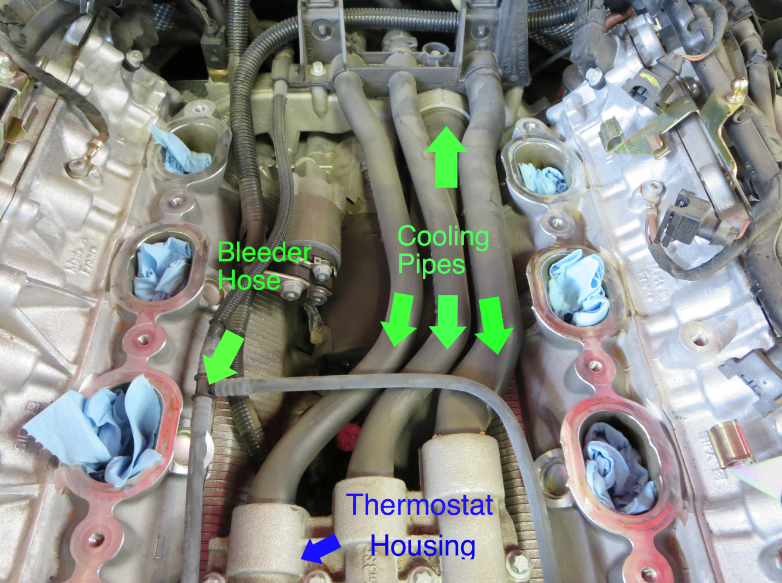

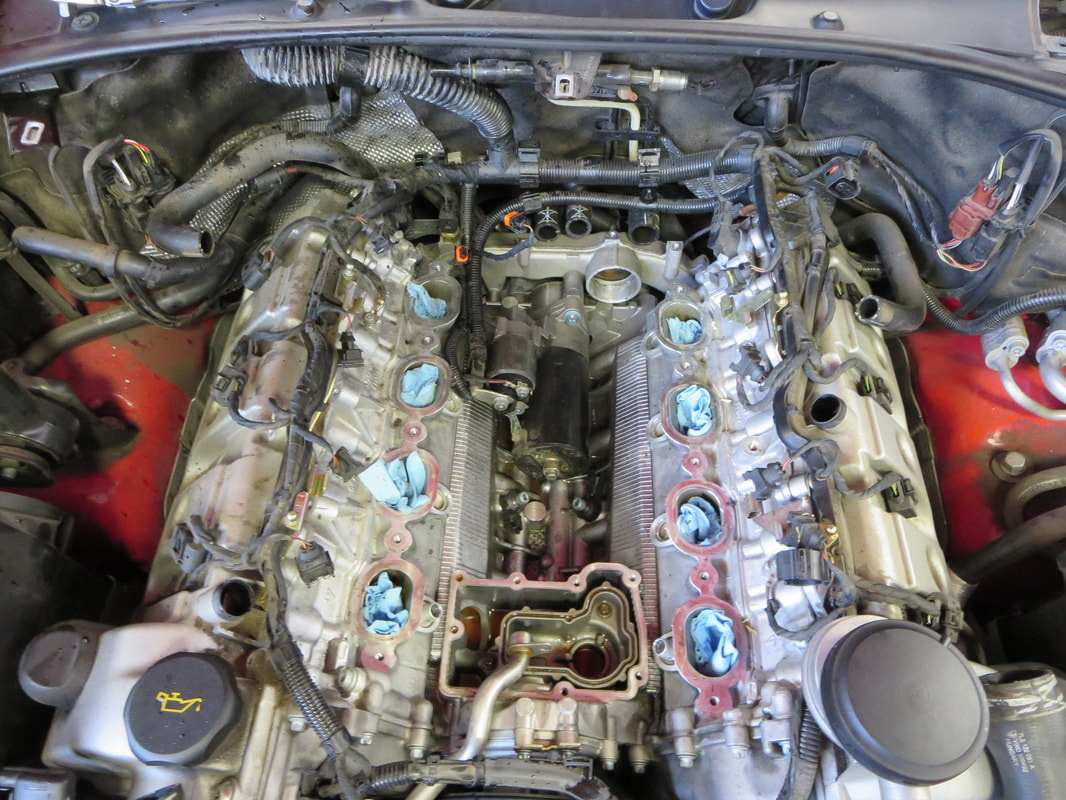

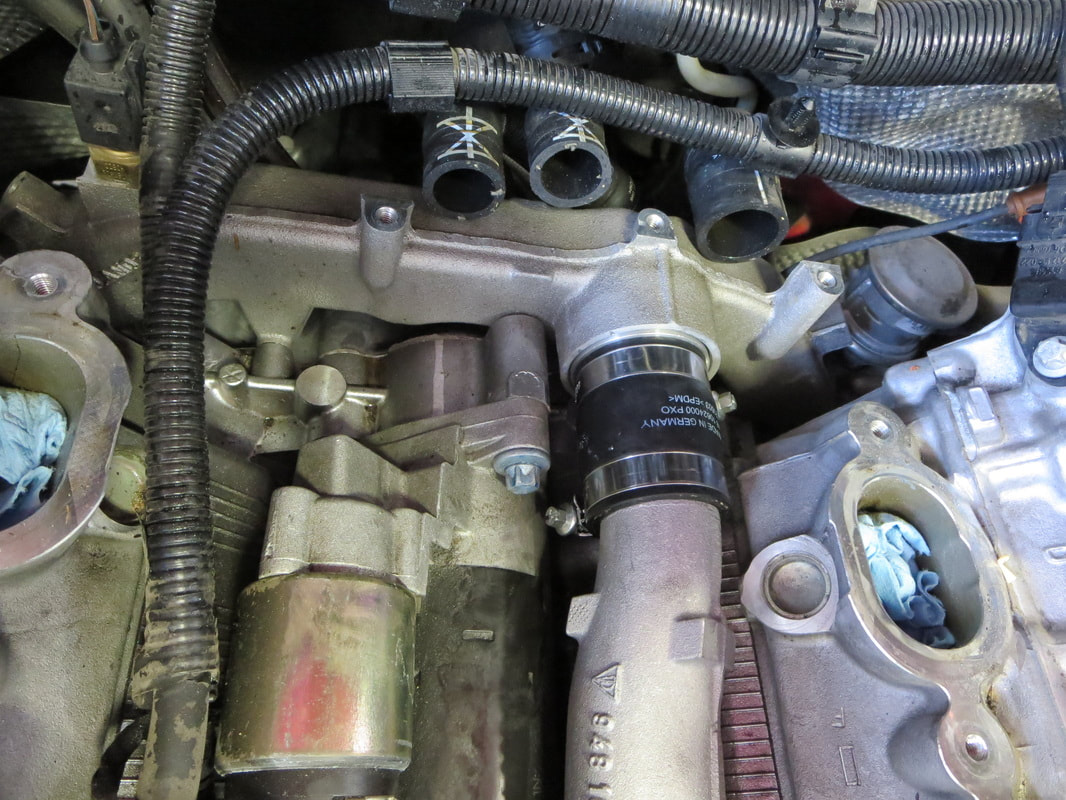

These adjustments to cam timing and valve lift are activated by the DME(engine control unit) by way of solenoids that open, allowing pressurized oil flow into their given chambers. When this activation is interrupted for any reason, the DME registers a fault. Fault Code P0021 This fault occurs when camshaft timing activation is inhibited. There are several reasons that this fault could occur but the most common reason is blocked oil flow into the variable cam sprocket. When this happens, the camshafts must be removed and repaired/replaced in order for the fault code to clear. Cayenne Cooling Pipe Failure10/2/2013 I doubt the engineers at VAG expected this to happen. And that's okay, right? We're human and this is no Radio Flyer wagon. The early Cayenne models that are equipped with V8 engines have an achilles heel: The plastic pipes that carry coolant located underneath the intake manifold are cracking, effectively spilling coolant to the external surfaces of the engine: right where you don't want it to be. This causes inconvenience, unforseen expense and grave disappointment because it's a Porsche Sports SUV and this kind of thing just shouldn't be happening! Here is a glimpse of this unfortunately common problem and what we do to solve it. Click on the photos to enlarge and read on...... Joe LeggsHusband, Father, Technician Archives

October 2016

Categories |

RSS Feed

RSS Feed